In a busy warehouse, safety isn’t just a policy—it’s the foundation of smooth, efficient operations. Forklifts move fast, goods are stacked high, and workers are constantly on the move. In this environment, even a moment of inattention can lead to costly accidents. That’s where XRLL’s Forklift Alert Systems come in.

With advanced technology like warehouse traffic sensors, anti collision sensors, and intelligent warning systems, XRLL Lighting is transforming how warehouses prevent accidents. These solutions don’t just beep and flash—they think, adapt, and protect.

Why Forklift Safety Should Be Every Warehouse’s Priority

Risks of Forklift Accidents

- Human injury and loss of productivity – Collisions can lead to serious harm, not just for operators but also for pedestrians working nearby.

- Damage to goods and infrastructure – A single accident can destroy valuable inventory or damage racking systems, causing additional repair costs.

- Costly downtime – Even minor incidents can halt warehouse operations, impacting delivery schedules and customer satisfaction.

- Legal and compliance risks – Failure to follow safety standards can result in regulatory penalties or insurance complications.

How Technology Reduces These Risks

- Real-time monitoring – Systems like XRLL’s use warehouse traffic sensors to detect movement before it becomes a problem.

- Early warnings – Operators get instant alerts, giving them time to slow down or stop before impact.

- Smart detection logic – Unlike basic alarms, XRLL’s solutions only activate when both forklift and pedestrian movement are detected, reducing unnecessary interruptions.

Key Features of XRLL Forklift Alert Systems

Advanced Warehouse Traffic Sensor Technology

- Dual-side detection – Activates only when movement is detected on both sides of a corner, such as a pedestrian and a forklift approaching simultaneously.

- Reduced false alarms – Intelligent algorithms minimize unnecessary alerts, keeping operators focused on real risks.

- 6-meter detection range – Covers blind spots effectively, giving operators extra reaction time.

- Adaptive calibration – The system automatically adjusts to its environment within 30 seconds for consistent performance.

Forklift Collision Prevention System

- Precise movement detection – Alerts continue for 3 seconds after motion stops to ensure awareness.

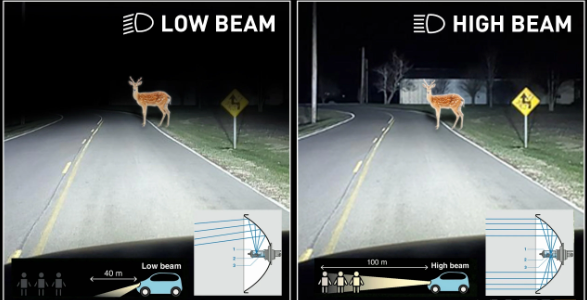

- Low-light performance – Works reliably even in dimly lit warehouse areas.

- Integration with anti collision sensors – Enhances accuracy and prevents damage to both people and goods.

Dual Warning System for Maximum Visibility

- 80dB adjustable buzzer – Three volume settings (high/low/off) to suit different work environments.

- High-brightness red LED strobe – Focused light beam for better visibility in busy warehouse zones.

- Synchronized sound and light alerts – Reinforces warnings to ensure no one misses a potential hazard.

Ultra-Long Battery Life with Wireless Design

- Powered by three D-size batteries – Included in the standard package.

- Up to 12 months runtime – In low-volume mode, perfect for long-term deployment without frequent maintenance.

- Blue low-battery indicator – Prevents sudden power loss by alerting maintenance staff in advance.

Industrial-Grade Easy Installation

- Strong magnetic mount – Ideal for attaching to metal shelving or racks.

- No wiring, no drilling – Can be set up in under 3 minutes without disrupting operations.

- Ergonomic placement – Best installed at 1.5–1.8 meters for optimal visibility and safety compliance.

High Adaptability Across Different Scenarios

- Ideal for warehouses, logistics centers, and factories – Especially in blind corners and high-traffic areas.

- Durable PS housing – Resists collisions and wear.

- Yellow-black color scheme – Improves visual recognition in industrial settings.

Cost-Effective Safety Investment

- One-year warranty – Ensures long-term reliability.

- Bulk purchase discounts – Perfect for multi-location warehouses.

- Low maintenance costs – Annual upkeep is as simple as changing the batteries.

Benefits of Using XRLL Forklift Alert Systems

- Fewer accidents – Reduce collision incidents by proactively alerting both forklift drivers and pedestrians.

- Lower operational costs – Save on equipment repairs, damaged goods, and downtime.

- Better compliance – Meet workplace safety regulations with advanced safety technology.

- Enhanced worker confidence – Employees feel safer and more productive in a well-protected environment.

Why Choose XRLL for Forklift Safety

- Proven expertise – Years of experience in developing Forklift Alert Systems and Forklift Collision Prevention Systems.

- Cutting-edge technology – Incorporating the latest anti collision sensor innovations for maximum reliability.

- Customer-focused solutions – From small warehouses to large distribution centers, XRLL tailors systems to your needs.

Conclusion

Safety in a warehouse doesn’t happen by chance—it’s the result of smart planning, the right equipment, and a commitment to protecting your team. XRLL’s Forklift Alert Systems are more than just alarms; they are intelligent safety partners equipped with warehouse traffic sensors, anti collision sensors, and advanced warning features to prevent accidents before they happen. If you want to keep your operations running smoothly while protecting both people and products, XRLL is your trusted partner in forklift safety.

If you have any questions about installation, need technical support, or want expert guidance on selecting the right Forklift Alert Systems for your warehouse, our team is ready to assist you.

📞 Tel: 0086-15818025687

📧 E-mail: service02@xrlledlight.com

Let XRLL help you create a safer, smarter, and more efficient workspace—because safety starts with the right technology.

Frequently Asked Questions (FAQ)

1. How does a Forklift Collision Prevention System work?

The Forklift Collision Prevention System works by continuously monitoring movement in high-risk areas. XRLL’s solution activates alerts only when both a forklift and a pedestrian (or another moving object) are detected on opposite sides of a blind corner. This reduces false alarms and ensures that warnings are only issued in genuine danger situations.

2. What is the detection range of XRLL’s system?

XRLL’s warehouse traffic sensor can detect movement within a 6-meter range. This makes it ideal for covering blind spots and busy intersections in warehouses, giving operators enough time to slow down or stop before a collision occurs.

3. What environments is the XRLL system suitable for?

The system is designed for warehouses, logistics centers, and factories—especially in areas with blind corners and heavy forklift traffic. Its durable PS housing is collision-resistant, and its yellow-black color scheme ensures high visibility.

4. Is there a warranty or bulk discount?

Yes. XRLL provides a 1-year warranty for all Forklift Alert Systems. Bulk purchase discounts are also available for companies looking to equip multiple facilities.