Forklifts are basically material-handling equip ment that becomes integral in very hectic indus trial settings such as warehouses, manufacturing facilities, and distribution centers. For this risk to be averted, the introduction of forklift warning lights has become an average safety measure.

This write-up will take a plunge into the importance of these lights, emphasizing the forklift blue light, blue safety lights for forklifts, and the forklift safety zone light; it will also decode meanings behind forklift dashboard symbols.

What Is the Warning Light on a Forklift?

What is a Forklift Warning Light?

In workplaces such as warehouses, factories, and construction sites where the noise level is high and the actions of others are difficult to see or detect, safety is always the first priority. Forklift warning lights serve the critical function of providing a highly visible clear signal to those around the worksite where forklifts are present and/or moving.

In situations where the sound of a horn might get lost to the noise of activity, lights provide an additional safeguard by making the forklift more visually conspicuous and making the operator’s actions easier to watch for thus trying to prevent an accident before it happens.

Types of Forklift Warning Lights

- Forklift Blue Light

Projects a bright blue beam onto the floor, typically 10 to 20 feet ahead or behind the forklift, signaling its approach to pedestrians.

- Red Zone Lights

Create a visible boundary around the forklift, indicating the safe distance pedestrians should maintain.

- Strobe Lights

Flashing lights that draw attention to the forklift’s presence, especially useful in low-visibility conditions.

- Forklift Safety Zone Light

Combines red and blue lights to delineate a safety perimeter around the forklift, enhancing awareness of its operational area.

Importance of Forklift Warning Lights

- Enhanced Visibility

Visual cues are more noticeable in noisy environments where auditory warnings may be missed.

- Accident Prevention

Follows the designated path for the forklift so it avoids accidents with pedestrians and other vehicles.

- Compliance with Safety Standards

The policy supports OSHA guidelines which state that powered industrial trucks must possess visual warning devices.

Why Do Forklifts Need Warning Lights?

Enhancing Pedestrian Safety

- Visual Alerts

The visual display from forklift blue lights alerts people to the forklift’s location so they can avoid its path.

- Preventing Blind Spot Accidents

Warning lights mounted on forklifts help pedestrians detect their approach in areas with limited visibility which decreases unexpected interactions.

Improving Operator Awareness

- Feedback Mechanism

The lights function as operational feedback devices which show operators the current status of the forklift.

- Dashboard Indicators

Operators must understand the symbols and meanings on forklift dashboards to respond correctly to alerts while ensuring safe operation.

Facilitating Compliance with Safety Regulations

- OSHA Guidelines

OSHA recommends using visual warning devices for safety enhancement though it does not set specific requirements for warning lights. The installation of these warning lights shows dedication to maintaining workplace safety protocols.

Reducing Noise Pollution

- Silent Warnings

High noise environments benefit from visual signals such as blue forklift safety lights which replace auditory warnings and reduce noise pollution.

Cost-Effective Safety Measure

- Accident Prevention

Investing in warning lights can lead to significant savings by preventing accidents, thereby reducing costs associated with injuries, equipment damage, and downtime.

Benefits of Forklift Blue Lights

High Visibility

- Distinct Color

The blue light stands out against typical warehouse backgrounds, making it easily noticeable.

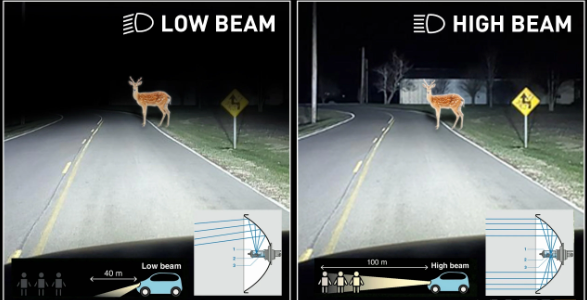

- Long-Range Projection

Projects a beam 10 to 20 feet ahead or behind the forklift, providing ample warning time for pedestrians.

Enhanced Safety in Low-Light Conditions

- Night Operations

Particularly beneficial during night shifts or in dimly lit areas, ensuring the forklift’s presence is always visible.

Increased Alertness

- Psychological Impact

Studies suggest that blue light exposure can increase alertness and reduce reaction times, contributing to a safer work environment.

Durability and Low Maintenance

- LED Technology

Blue safety lights utilize LED technology, offering longevity and resistance to vibrations and shocks common in industrial settings.

Why Choose Us?

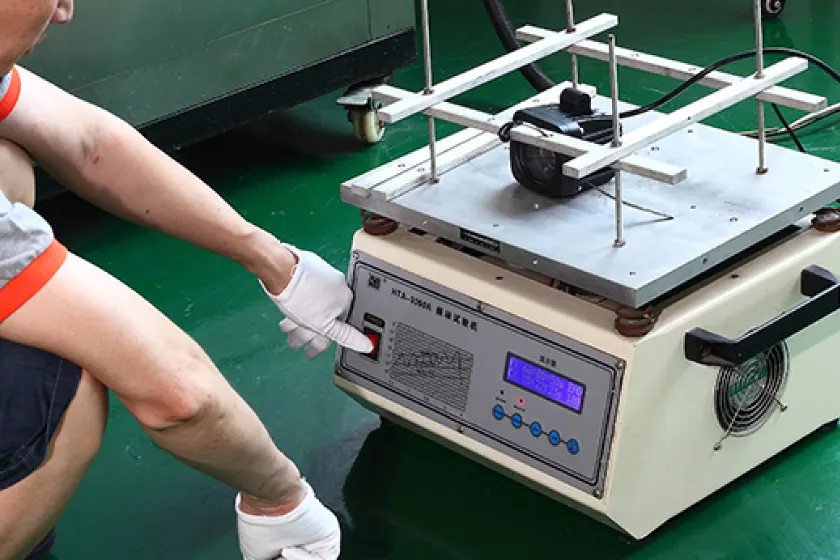

• Our products can conform to the standards of E-mark/Dot/IP68/CE and so on.

• Regarding the circuit board, our engineer can settle anti-interference/Electro Magnetic Compatibility/Anti-inrush current…

• Regarding raw materials and products, we strictly control quality. Tested by low temperature circumstances/ salt spray/HI/Vibration/waterproof,/Aging test.

Conclusion

The integration of warning lights, particularly the forklift blue light, blue safety lights for forklifts, and fThe integration blue safety lights for forklifts and safety zone lights for these vehicles carry an essential function in boosting safety standards inside workplaces. When combined with a clear understanding of forklift dashboard symbols, these visual safety tools become powerful allies in preventing accidents.

As industrial settings grow more complex, prioritizing and maintaining these safety measures is key to protecting both workers and valuable equipment.

FAQs

What does an exclamation sign indicate on a forklift?

- Hyundai Forklift Fault Codes list

An exclamation sign within the engine symbol, means turn the engine off immediately and schedule to inspect – that means this vehicle has a serious issue and needs attention right away.

- Battery warning

If the battery icon lights up while operating, make sure you check the charging system on the forklift, to verify it is working and charging the batteries.

What are the blue warning lights on forklifts for?

The blue lights on forklifts represent a vital safety purpose; they alert other individuals that a forklift has entered the area and there is either pedestrian traffic or another individual crossing the path of the forklift. Blue lights help in making a safe work environment when you, as a pedestrian, understand that the forklift is signalling movement— especially when it is in reverse mode.

What does a forklift in a yellow triangle mean?

Meaning: Potential hazard, warning and caution.

Color: Yellow background with black text and symbol.

Symbol: A triangle with a black outline with some sort of graphical warning symbol.

What is the Golden Rule of Forklift Operations?

The Golden Rule for Forklift Operations is providing safety as a priority:

“Always operate a forklift as if people are nearby—even if you don’t see anyone.”