Quality control for LED work lights in 2026 isn’t just a checklist—it’s an essential strategy for brands, factories, and importers who want to survive in a market driven by innovation and performance. With customer expectations rising and global regulations becoming more stringent, delivering a stable, powerful, and reliable LED work light has never been more important.

Whether you’re a professional buyer, a global distributor, or a LED Work Lights Manufacturer, mastering QC ensures your products shine brighter, last longer, and stand out in competitive industries where even the best laser whip lights set new quality benchmarks.

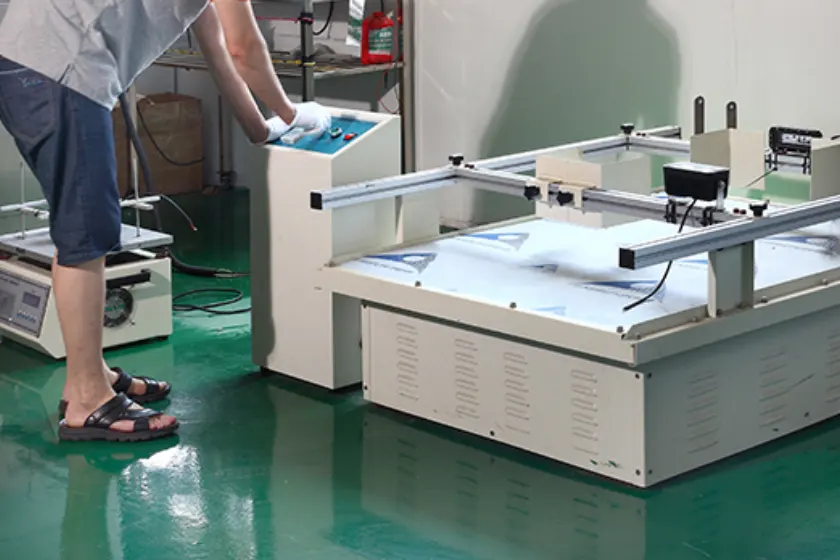

In-Process Quality Control (IPQC)

In-process quality control ensures product stability while the light is being manufactured. This is where engineers catch assembly mistakes and structural weaknesses before they turn into expensive rework.

Soldering & PCB Assembly

Proper soldering ensures long-term electrical stability. Automated optical inspection (AOI) systems check for cold solder joints, missing components, polarity errors, and alignment accuracy. Manual technicians then verify critical zones such as power pads and driver terminals. A single weak soldering point may cause intermittent lighting failure, so this step is essential for building consistent product reliability.

Assembly Alignment & Mechanical Fit

LED modules, reflectors, lenses, and housings must fit together with precision. QC inspectors verify screw torque, gasket placement, and cable routing to ensure both structural integrity and waterproof performance. Misaligned components may shift beam patterns, introduce rattling noises, or weaken waterproofing, all of which reduce product lifespan. A standardized assembly procedure ensures every unit is built to an identical standard.

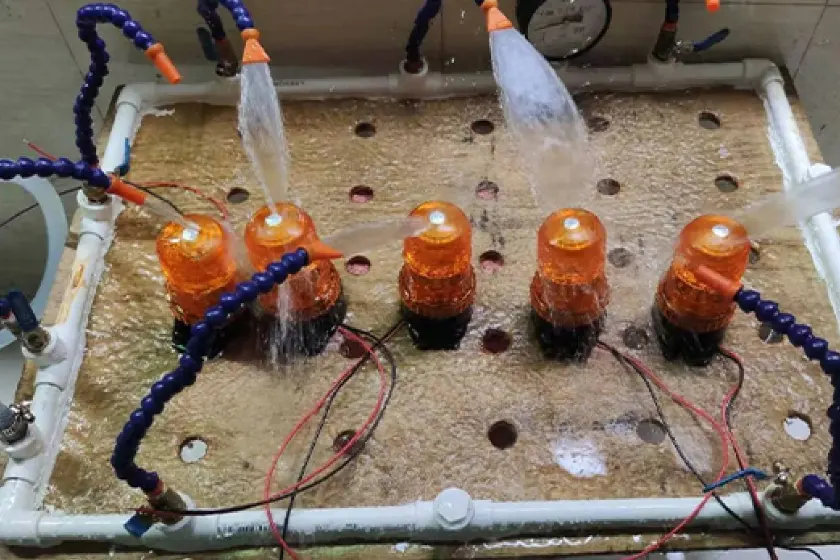

Waterproofing & Seal Application

Waterproof performance depends heavily on correct sealing during assembly. Inspectors evaluate the silicone seal uniformity, gasket compression, and screw tightening sequence. Even a small sealing defect can lead to water ingress during rain or pressure washing. To ensure real-world reliability, factories often perform spot water-pressure simulations during the assembly stage.

Reliability Testing

Reliability tests simulate harsh environments where LED work lights are commonly used, such as construction sites, mining fields, automotive repair zones, or emergency rescue operations.

Thermal Shock Testing

Thermal shock tests expose the product to rapid temperature swings, such as –40°C to +80°C cycles. This validates whether the lens, housing, and sealing materials can withstand extreme conditions without cracking or deforming. It also evaluates solder joint durability and LED color stability under stress.

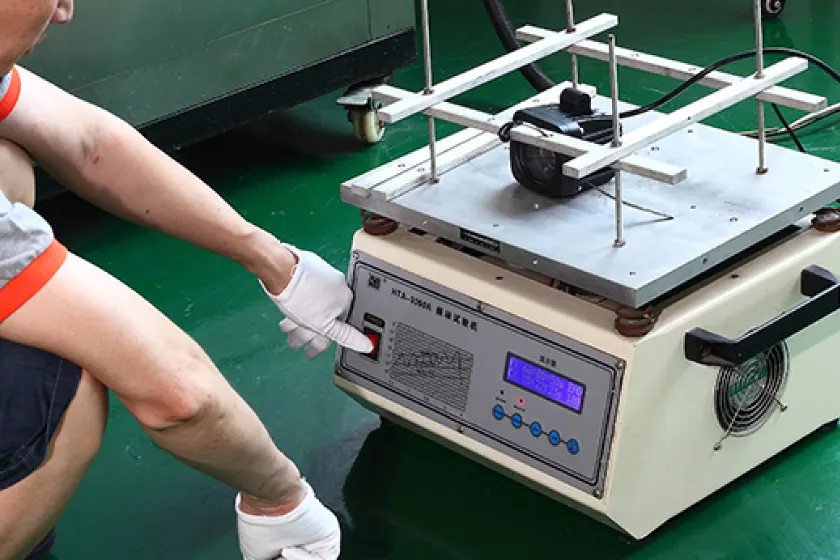

Vibration & Impact Testing

LED work lights used on vehicles or machinery must withstand vibration. QC teams conduct vibration simulations based on the IEC and automotive standards to ensure internal components remain stable. Any loose connectors or weak internal structures are identified during this process, reducing the risk of failure during real-world usage.

Humidity, Salt Spray & Corrosion Testing

Outdoor and marine environments introduce high humidity, salt exposure, and chemical corrosion risks. Salt spray chambers simulate long-term exposure to sea air, ensuring housings and screws do not rust prematurely. This test is especially important for aluminum housings and stainless steel components.

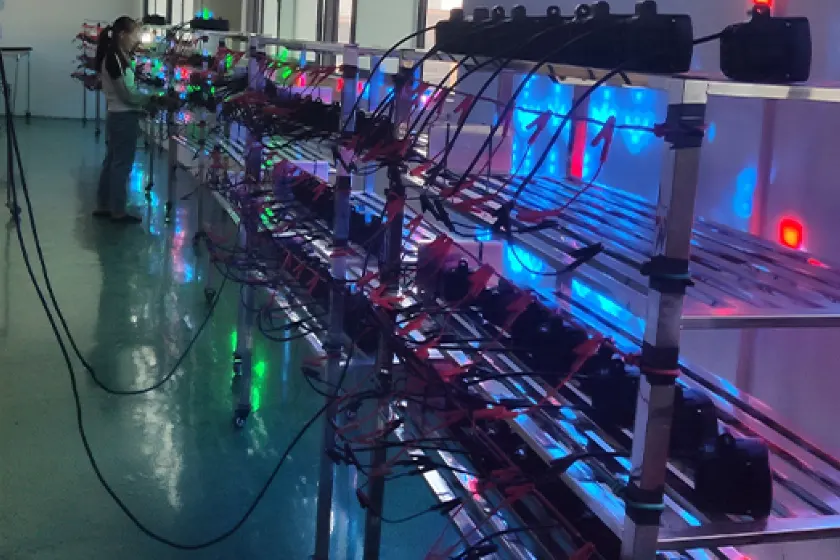

Aging (Burn-In) Testing

Before packaging, LED work lights undergo an 8–24 hour burn-in test at full load. This step catches early failures caused by soldering defects, heat issues, or weak components. Lights that survive burn-in testing demonstrate much higher long-term reliability in customer applications.

Waterproof & Outdoor Performance Tests

Because LED work lights are often used outdoors, waterproofing is a critical performance factor. Proper testing ensures long-term durability even in rain, mud, or high-pressure environments.

IP65/IP67/IP68 Testing

Depending on product design, manufacturers test for dust resistance, water jets, or full submersion. For example:

- IP65: high-pressure spray simulation

- IP67: 1m submersion for 30 minutes

- IP68: deep-water or long-duration submersion

Lights must show no signs of water entry, fogging, or short-circuiting.

Pressure & Submersion Simulation

Advanced QC labs use water-pressure tanks to simulate real-life scenarios such as heavy rain on construction sites or underwater exposure for marine work lights. This ensures seals, screws, and connectors maintain integrity even under extreme conditions.

Photometric & Electrical Performance Testing

Photometric tests measure actual lighting performance, while electrical tests verify safety and energy efficiency.

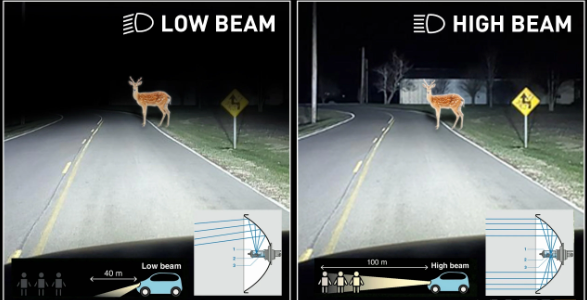

Lumen Output & Beam Pattern Evaluation

QC engineers test luminous flux (brightness), beam angle consistency, hot-spot distribution, and uniformity using an integrating sphere and optical goniometer. Even slight inconsistencies can change how the light performs during field use, so every model must meet its published specifications.

Color Temperature & CRI Testing

Color temperature (CCT) and color rendering index (CRI) determine visual clarity during work tasks. Factories ensure CCT deviation stays within ±200K of the target and maintain a CRI suitable for the application. Consistent CCT ensures multiple lights used together produce uniform illumination.

Electrical Safety & Surge Protection

Electrical performance is verified through surge tests, insulation resistance evaluation, and stability under fluctuating voltage. LED work lights must maintain stable output even during voltage spikes, especially in industrial environments with large machinery.

Final Transportation Simulation Test

Before shipment, a final inspection ensures the finished products meet all cosmetic, functional, and packaging standards.

Appearance & Label Checking

Inspectors check for scratches, paint unevenness, lens clarity, and correct labels for voltage, wattage, and certifications. Accurate labeling reinforces safety and compliance for international shipments.

Functional Checking

Each unit undergoes a functional ON/OFF test, brightness test, and short burn-in test. QC also verifies waterproof integrity, connector fit, and heat performance under full load.

Packaging & Drop Testing

Proper packaging prevents damage during transport. Factories perform drop tests based on ISTA standards to verify that foam inserts, boxes, and labels protect the product during international shipping.

FAQ (2026 Updated)

1. How to check the LED work light quality?

To check LED work light quality, start by evaluating brightness, uniformity, and heat dissipation. A high-quality light should maintain stable brightness without flicker or dimming after operating for 10–15 minutes. Inspect materials such as aluminum thickness, lens clarity, and waterproof sealing to determine build integrity.

Make sure the light carries certifications such as CE, RoHS, or UL to confirm safety and compliance. Finally, buying from a reputable LED Work Lights Manufacturer ensures product traceability and consistent quality across all batches.

2. What is the ISO standard for LED lights?

LED lighting products in 2026 commonly follow ISO 9001 (quality management), ISO 14001 (environmental management), and ISO 45001 (worker safety). For photobiological safety, ISO/IEC 62471 remains the global benchmark, ensuring lights do not cause eye or skin hazards.

These standards ensure manufacturers implement strict process controls to produce safe, consistent, and environmentally responsible lighting products. When a factory maintains multiple ISO certifications, it reflects strong internal management and quality assurance capability.

3. How to know the original LED work light?

To identify an original LED work light, check whether the product has verifiable model numbers, certified labels, and consistent branding across packaging and documentation. High-quality lights use stable LED chips with uniform color temperature and proper waterproof seals, while counterfeit products often cut corners in these areas.

Authentic manufacturers provide warranties, test reports, and certifications, making it easy to verify product authenticity. Purchasing directly from a trusted LED Work Lights Manufacturer or authorized distributor ensures you receive genuine products with reliable performance and after-sales support.

Conclusion

As 2026 pushes LED technology into new levels of performance and innovation, rock-solid quality control becomes the backbone of every successful lighting brand. From material inspection to vibration tests and photometric analysis, each step ensures your LED work lights perform reliably in real-world conditions.

Whether you’re designing heavy-duty work lights or even high-performance accessories like the best laser whip lights, combining strict QC standards with modern testing tools is the key to building durable, high-value products. Partnering with the right LED Work Lights Manufacturer helps your brand deliver consistent excellence—project after project, year after year.